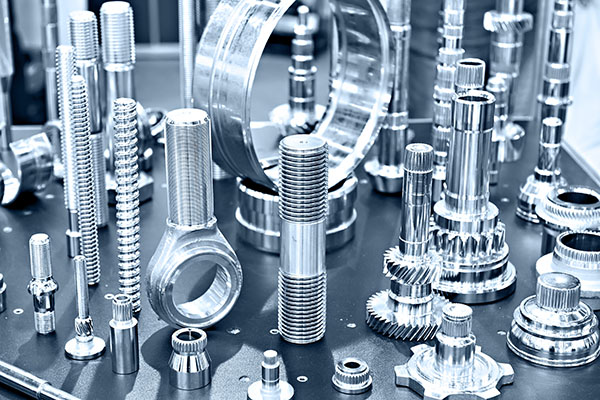

For more than 40 years, our surface specialists have been making an important contribution to the development of new products and technologies; galvanized surfaces are used in many sectors of the economy. Even though electroplated surfaces often make only a small part of the value of the end product, they still play a major role in the development of innovative products. In addition, electroplating helps to extend the service life of many everyday objects. For example, just one kilogram of zinc can protect a ton of screws against corrosion. In this way, electroplating prevents the destruction of valuable materials and makes an important contribution to protecting the environment and conserving resources.

Zinc (acidid)

Acid zinc processes are particularly suitable for protecting steel, cast and forged parts against corrosion. Very well adhering layers are deposited, which provide very good cathodic corrosion protection and thus sustainably protect your components from corrosive wear. The resulting layer thickness is up to 30 µm.

Advantages:

- High cathodic corrosion protection

- Functional surface with high optical quality

- Suitable for almost all steel, cast and forged materials

- Low hydrogen embrittlement

Our plants offer space for projects with dimensions up to 2700 x 600 x 1500 mm.

For more information, please feel free to contact us.

Zinc (alkaline)

Alkaline zinc processes are among the oldest and most widely used surface processes to protect steel parts from corrosion. Very well adherent coatings and cathodic corrosion protection provide lasting protection for the component. The resulting layer thickness is up to 30 µm.

Advantages:

- High cathodic corrosion protection

- Functional surface with uniform layer distribution

- Particularly suitable for complicated geometries

- Internal coating possible via internal anode

Our plants offer space for projects with dimensions up to 2700 x 600 x 1500 mm.

Zinc / Nickel

Zinc-nickel coating withstands significantly higher temperature than zinc plating. Components coated with zinc-nickel are also better protected against aggressive environmental stresses such as road salt and climatic influences.

Advantages:

- Bending and flanging resistance

- High long-term corrosion protection against temperature, road salt and climatic stresses

- No contact corrosion with aluminum

- Good thermal load capacity

Our plants offer space for projects with dimensions up to 2700 x 600 x 1500 mm.

Anodizing

Anodizing aluminum, also called anodic oxidation, eloxation or eloxal, provides the most durable corrosion protection for aluminum. In this process, the aluminum surface is converted into aluminum oxide in an electrochemical process. This oxide layer is ceramic hard, transparent and firmly bonded to the base material.

Advantages:

- Organic and electrolytic coloring possible

- Electrical Isolation

- Decorative, effective appearance and haptics

- Improved corrosion protection

We can offer this process for sizes up to 2700 x 1500 x 600 mm with organic and electrolytic coloring possibilities. The layer thickness is up to 25 µm.

Hard Anodizing

A variant of anodizing is hard anodizing. Here, particularly hard, friction-resistant and thick coatings are produced which are able to withstand the highest requirements in terms of wear, abrasion, corrosion resistance and dielectric strength.

Advantages:

- Highest corrosion protection

- Very high surface hardness

- Very good abrasion resistance

- Physiologically harmless, suitable for foodstuffs

We can process dimensions up to 2700 x 1500 x 600 mm.

For further information please contact us.

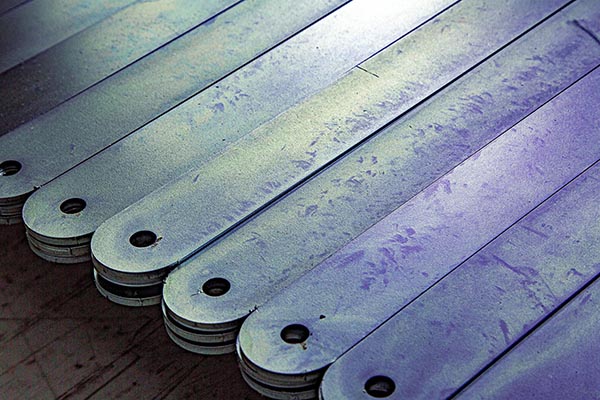

Burnishing

Burnishing is a surface treatment without coating that produces a smooth, textureless black appearance and is highly resistant to bending and abrasion. The shade of black depends on the material quality, the surface treatment and the composition of the burnishing bath.

Advantages:

- Conductivity and magnetic properties of the base material are not affected

- Conditional corrosion protection is only possible by insertion of oil

- No dimensional changes of the components

Our plants offer space for projects with dimensions up to 1000 x 500 x 600 mm.

Yellow Chromating (aluminum)

The most common function of chromate coatings is corrosion protection, but they can also be used to create an adhesive base for subsequent coatings, as tarnish protection (for silver), to reduce fingerprint sensitivity, or to change appearance (gloss, color).

Advantages:

- Corrosion protection

- Adhesion primer for paints, powder coatings and adhesives

- Low surface resistance

- Visual enhancement

Our plants offer space for projects with dimensions up to 2700 x 1500 x 600 mm process.

Passivation (surtec 650)

The chemical process of Al passivation produces a colorless, faintly iridescent coating. The resulting surface coating is also chromium Vl-free and RoHS and REACH compliant.

Advantages:

- suitable for post-treatment of anodized coatings

- excellent corrosion protection

- very well suited as an adhesion primer for paints, powder coatings

- approved by GSB and QUALICOAT

- low surface resistance

- solderable

Our plants offer space for projects with dimensions up to 2700 x 1500 x 600 mm.

For more information, please contact us.